Cost Reduction

What will you achieve when you work with us?

You will find more opportunity in your organization than is thought to exist

Your people will quickly realize opportunities that seem impossible today

Your people will own the solutions and success, making them sustainable

Suppose you are working in operations or manufacturing today. You know you will be asked for more – more growth, more output, more cost-cutting, more improvement – regardless of what you have already achieved. Attaining more, especially when you have less to work with, requires your organization to do two things very well: choose the top opportunities to tackle and realize them as quickly as possible.

These opportunities will be unique to your facility and generally fall into one or more categories below. These are our bread and butter when it comes to manufacturing operations improvement.

Raw material waste or scrap reductions (including overfills)

Labour efficiency increases

Overall cost reductions (fixed and variable costs)

Scheduling or other cyclical event duration/frequency improvements

Complementing your teams to be successful

Some of our clients have well-established improvement processes such as lean manufacturing, six sigma initiatives, and Continuous Improvement organizations to drive change; others have only started to build these capabilities. From our perspective, regardless of where you sit on this spectrum, your improvement rate can always be increased to enable you to achieve a lot more. Our approach is straightforward:

We seek to understand where all of the opportunity sits in your organization and its magnitude.

We tackle the most valuable opportunities with the appropriate tools, breaking the constraints that may have prevented progress in the past.

We do this collaboratively with your people so that the solutions are theirs and, therefore, more permanent and sustainable. What makes us the best at what we do is our Abundant Thinking mindset:

The belief that more is always possible.

The motivation to run after it in the face of many constraints.

The capability to lead others to realize even the most challenging opportunities.

In working with our clients, we’ve partnered in several ways, ranging from self-directed learning to on-site support.

How we help

We have a couple of tools that we are particularly enthusiastic about because they outperform any others that we have seen:

Zero-Based Analysis (ZBA) - Find all of the opportunity in your organization. Organizations typically see three to four times more opportunity when they apply ZBA over their current view.

Variable Analysis Problem Solving - All problems can be solved, and the solutions are often elegantly simple. The challenge is the process of finding the root cause.

How we do this together depends on your organization’s strengths, culture, resources, time frame, and a whole host of other factors. No one improvement system works for every organization. We want to help you build or improve yours, borrowing from all of the approaches that exist to create what will work best for you.

One constant, however, is starting with early, tangible, breakthrough results. Successful change begins with step-changes in performance, not reports or lists of recommendations. Generating and sustaining a large result generates excitement and pull to do more, especially if previously thought to be impossible. It also teaches us what works well and where the organization is already strong.

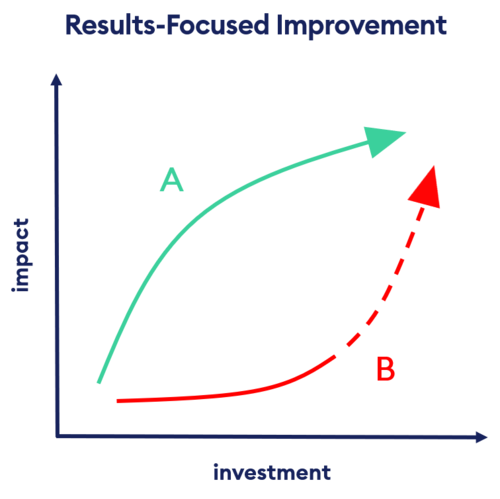

Path A (Success):

Leading with early results and feeding off real, tangible improvements to grow excitement and buy-in is the most effective and sustainable path to transform your organizational performance. We help to build culture and capability around the results that people drive and will own themselves.

Path B:

Research shows that greater than 90% of change efforts that invest heavily in capability and culture change without emphasising results fail. Wide-scale training of off-the-shelf improvement methodologies rarely builds the momentum and ownership required to drive and sustain tangible results.