Cost Reduction Plans

A methodical, pain-free approach to develop your cost reduction plans

What Is Budget Season Like At Your Organization?

If it’s anything like most organizations, it’s chaotic and even a little contentious. The need to commit to next year’s performance objectives must be balanced with the ongoing search for cost reduction opportunities and development of improvement plans, all while keeping up with the day-to-day demands of running the business.

We’ve helped thousands of manufacturing facilities to analyze their cost of goods sold for improvement opportunities and have noticed a few common challenges that arise.

What are the key pain points in cost reduction plan development?

It always takes more time and effort than you think it will

Lacking a shared, consistent approach to opportunity analysis, combined with the resource constraints that all companies face, will ensure the process of finding enough cost reductions to satisfy business objectives drags on.

At times, it can feel like trying to get blood from a stone

After years of successive cost reduction initiatives, it can seem like there’s very little meat left on the bones of your cost structure.

Budget owners risk becoming committed to unrealistic expectations

Brainstorming, ideation and benchmarking are great for highlighting potential opportunities but offer very little on how to value these opportunities and put them in the bank. Senior executives (and consultants) are prone to believing in this potential before it is shown to be real, putting budget owners in the unenviable position of committing to an unrealistic plan.

What are the key pain points in cost reduction plan development?

It always takes more time and effort than you think it will

Lacking a shared, consistent approach to opportunity analysis, combined with the resource constraints that all companies face, will ensure the process of finding enough cost reductions to satisfy business objectives drags on.

At times, it can feel like trying to get blood from a stone

After years of successive cost reduction initiatives, it can seem like there’s very little meat left on the bones of your cost structure.

Budget owners risk becoming committed to unrealistic expectations

Brainstorming, ideation and benchmarking are great for highlighting potential opportunities but offer very little on how to value these opportunities and put them in the bank. Senior executives (and consultants) are prone to believing in this potential before it is shown to be real, putting budget owners in the unenviable position of committing to an unrealistic plan.

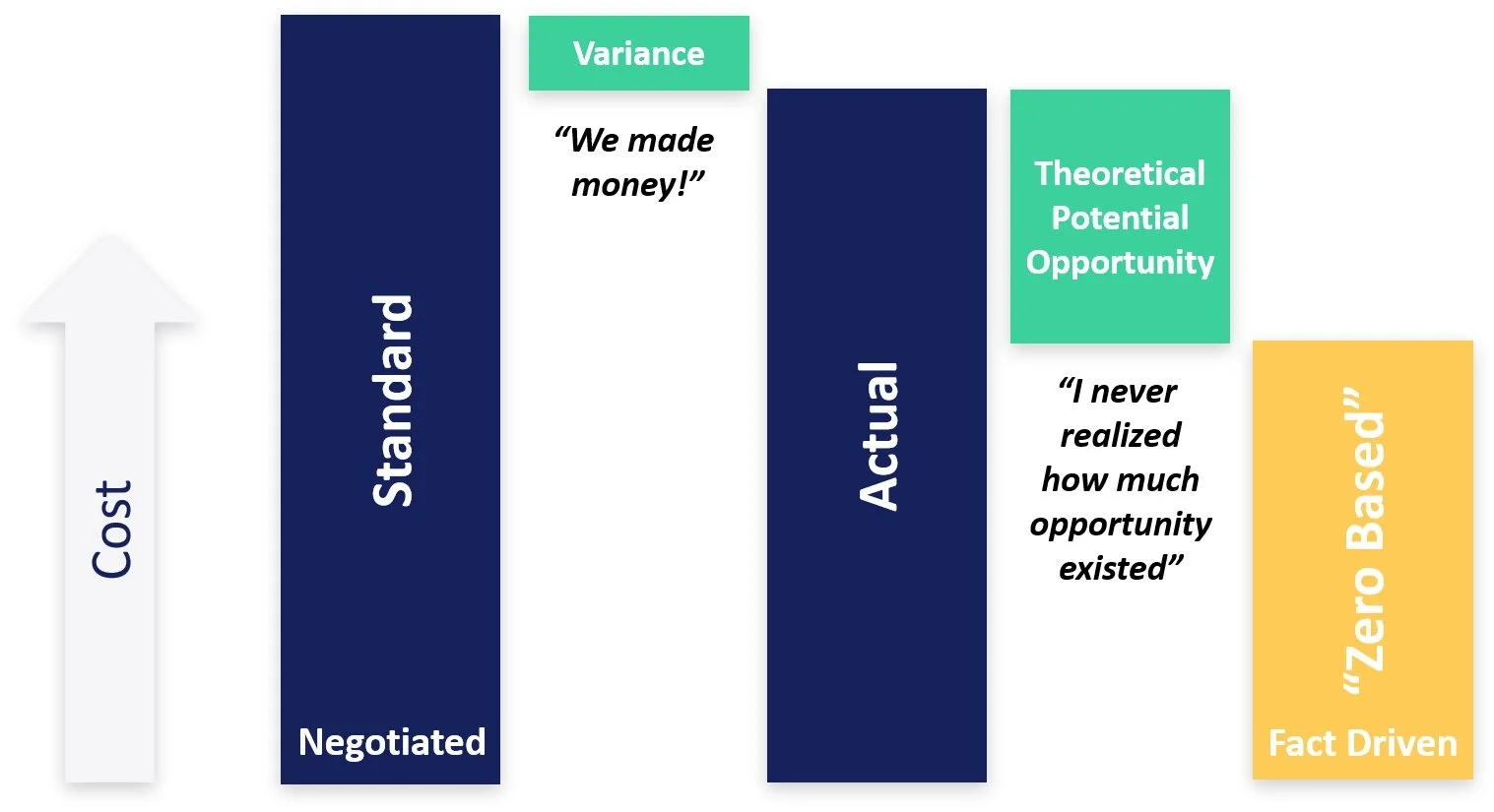

Zero-Based Analysis

Put all opportunities on the table and leave no stone unturned

Opportunity Radar

Align the organization around priorities

Developing a plan that meets your goals without making unrealistic commitments or sidetracking your team

We'll teach your team to apply Stroud's Zero-Based Analysis (ZBA) methodology for assessing the full potential of a manufacturing operation. It's an approach we've perfected over the past 20 years, helping clients across dozens of industries rapidly unearth all possible profit improvement and cost reduction opportunities in their manufacturing operations and develop improvement plans that are both aggressive and realistic.

We offer our Zero-Based Analysis in a remotely-delivered, educational format where we provide your team with the templates, training and coaching to perform a ZBA of your facility's labour and raw material costs.

Over the course of 6 weeks, your team will:

Develop their own data-driven Opportunity Radar depicting a comprehensive catalogue of your improvement opportunities, prioritized by value and complexity

Learn a consistent, repeatable process that they can apply year after year

Join a cohort of peers from other companies in the process of developing their own improvement plans at the same time

Have access to the full depth and breadth of Stroud's experience performing Zero-Based Analysis across a vast array of manufacturing types and formats

Be in complete control of their cost reduction plan and able to clearly articulate each logical step they took in its development